1. Advantages:

1. Using double slide into place device, reduce the cutting waiting times, increase production capacity.

2. Avoid artificial flap caused by the cracking of tin and part damage and other issues.

3. Avoid using blunt or fold, produced by mechanical stress.

4. Suitable for the finished plate arc and line cutting.

5. Suitable for small pieces of the final cutting, base plate of a mobile phone, PDA, PC interface card and so on.

2. Feature:

1.X10 zoom-in image makes programming easier&increase the accuracy of point setting.

2.Two sliding table provides simultaneously in-and-out movement to reduce the tack time for better productivity.

3.AUTO MARK offset system.CCD image could check&simulate the path or routing to reduce unnecessary mistake before cutting.

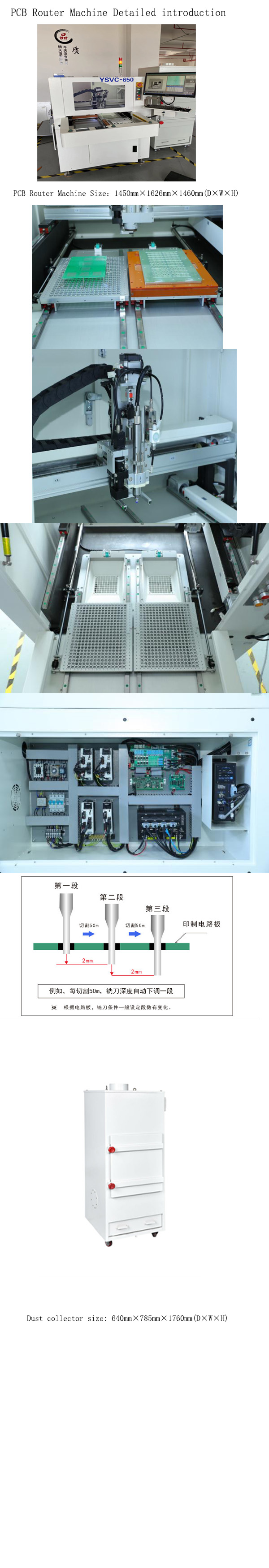

4. Has routing bit life time checking and alarm system to remind operator to change routing bits when it finish 120M cutting. And routing bit first 2mm cut the first miling point, middle 2mm cut the second milling point, the last 2mm cut the third milling point to increase its life time.

5. CCD image could check&simulate the path or routing to reduce unnecessary mistake before cutting.

3. Parts List:PCB Depaneling Automatic Tool / Blade Change System Large Twin Table -YSVC-650

| I. Hardware |

|

| SPINDLE | KAVO spindle |

| CCD | Sony 520 line industrial cameras |

| LENS | Computar EX2C |

| Screw | TBI Precision ground ball screw imports |

| Guide | HIWIN widening Imported linear guide rail |

| MOTOR | JiaBao LCF Series |

| I/O CONTRONL CARD | HFC PCI-9074 |

| DRIVER CONTRONL CARD | HFC PCI-9074 |

| I/O CARD | PCI-9074-64pcs/-38pcs |

| Static cleanup | STATIC-ST401A Series |

| Computer | (RMC-8401/6113LP4/300ATX/8651VNA/P4 2.8G 2CPU(S)/1G DDR/80G) |

| Machine interface | AOC LCD17",Logitech mouse |

| 2. software |

|

| Control system | Windows XP Professional (Service3,v.3244) |

| Operation GUI | English Windows XP |

| Program edit | Inline |

| Vision system | CCD AOTU offset |

| Control system | F 1.2.88 version |

4. Parameters:

| Overall |

|

| Dimensions(W*D*H) | 1370mm*1650mm*1450mm |

| Weight | 650KG |

| Height offset | 60~110mm |

| Manipulator |

|

| Motor type | JiaBao series |

| Positioning repeatability | 0.001mm |

| Axis working area(max) | 830mm*580mm*50mm |

| Work station |

|

| PCB fixation | standard,specialization |

| PCB loading/unloading | manual |

| PCB size (max) | 320*320mm(could be customized make) |

| PCB thick (max) | 5mm |

| Fixturing |

|

| Rigidity fixturing | Use client fixture |

| Fixturing fixation | machinery |

| Spindle Motor |

|

| Power | 150W |

| Spindle | 60000rpm/min |

| Protect | self/wind cooling |

| Change cutter | Specialization |

| Routing capability |

|

| Cutting speed(max.) | 80mm/s |

| Driving speed(max.) | 2500mm/s |

| Precision of cutting | 0.01mm |

| Vacuum System |

|

| Vacuum power | 3.5KW AC 380V |

| Vacuum | plumb |

| Utilities |

|

| Power | 2.0KW AC380V |

| Air supply | 4-6KG/cm2 |

| Programming |

|

| Program edit | Inline |

| Function edit | Line,arc,circula,U-curve |

| Program storage | HDD |

| Vision system | SONE colour CCD |

| milling cutter offset | AUTO |

| Vacuum setup | AUTO |

| Operation Monitors |

|

| Iindicator | Iindicator Machine state |

| tool check | Automatic detection tool life, the use of time testing |

| Motor protect | Have overheating, overload, low voltage protection function |

| motor over loading check | Have Overload, the line is normal, low voltage protection function |

| Tool usable time | Automatic detection tool life, |

| Data statistic | Separate board model, separating count, diverse counting methods |

| Error record | Software automatically records all alarms memory of machines |

| III. Accuracy |

|

| Axis precision | 0.001mm |

| Cutting precision | 0.1mm |

| IV. Safety |

|

| Working area protect | With four sealed protection |

| Door sensor | Front and rear safety door micro-switch sensor (optional) |

| Exigency stop button |

|

|

Model Number: |

YSVC-650 |

|

Weight: |

600kgs |

|

PCB Thickness: |

0.3-3.5mm |

|

Spindle: |

Germany KAVO |

|

Cutting Precision: |

0.1mm |

|

Positioning Accuracy: |

0.01 |

|

Warranty: |

1 Year |

|

Working Area: |

320*320mm(could Be Customized Make) |

|

Description: |

PCB Depaneling Machine |

|

Brand Name: |

YUSH |

|

Certification: |

CE |

|

Place Of Origin: |

China |

|

Minimum Order Quantity: |

1 set |

|

Packaging Details: |

plywood case |

|

Delivery Time: |

7 days |

|

Supply Ability: |

80 sets per month |

Email: caojun@hk-yush.com / evaliu@hk-yush.com