Application Area:

1.SMT&PCB:FPC soft board dispenser/Underfill/Component package…

2.Module:VCM,CCM,Vibrating motor,MEMS,BOT-RUBBER…

3.Semiconductor Packaging:Chip level bottom fill/Dome Coating/Glob top…

4.Automobile Electronic:RTV Component reinforcement/ECU thermal conductive adhesive/Bearing grease point gluing…

Characteristic And Advantage:

1.High precisionX-Y-Z axle;

2.vision algorithm support mask matching,wavelet transform ,contour recognition,shape catch;

3.support dot,line,circle(arc-shaped),ellipse,Screw filling,rectangle filling……

4.stabilization high speed move platform,C++platform control software operation simple,easy programming ;

5.Communication function can be connected with customer SFL system,according to customer SFL system instruction finish Selective dispensing;

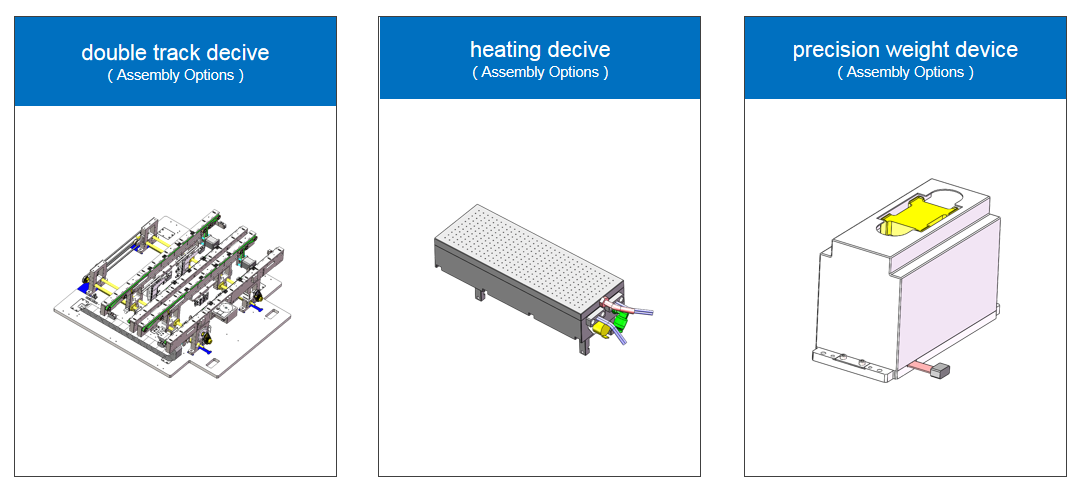

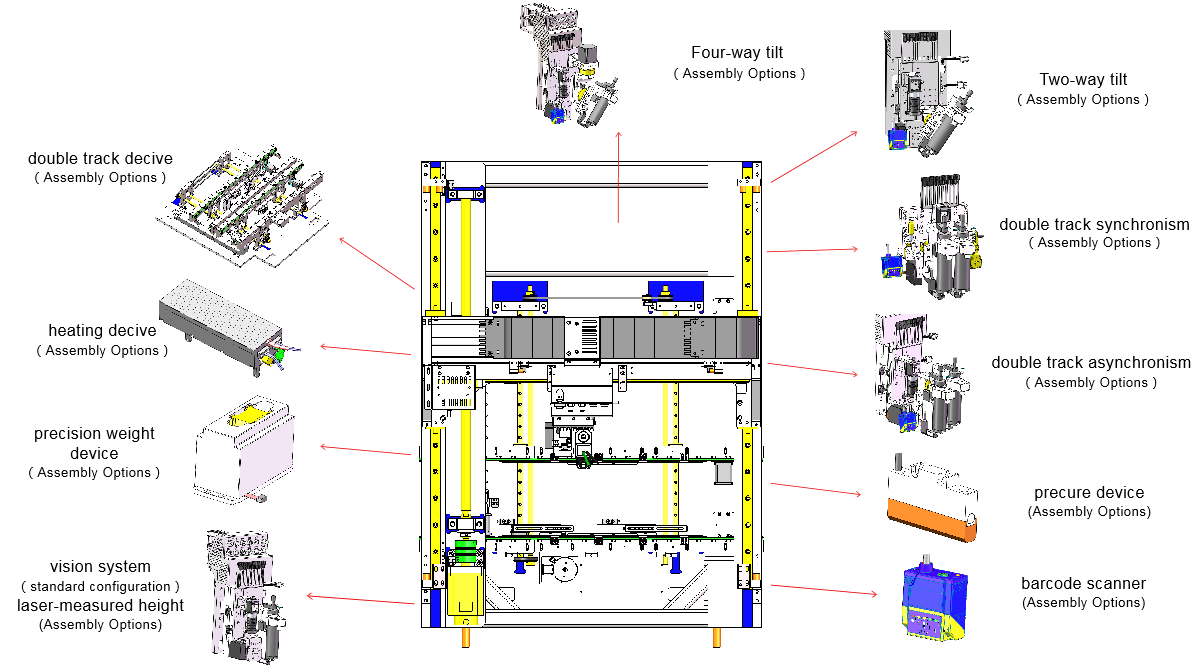

Customizable Function

According to customer’s requirement custom function,accord with different industry manufacture requirement

1.Assembly Options:one valves one track,one valves double track,doubole valves one track,double valves double track ,double track synchronism,double track asynchronism

2.Preheat PCB board front and back,Workspace heating function,Three-stage heating platform is optional at most

3.Assembly Options weight device,intelligent control and monitor the weight of glue

4.Bidirectional tilting device four-component tilting device

5.Barcode Scanner

6.UV Precure

7.SFL communication system

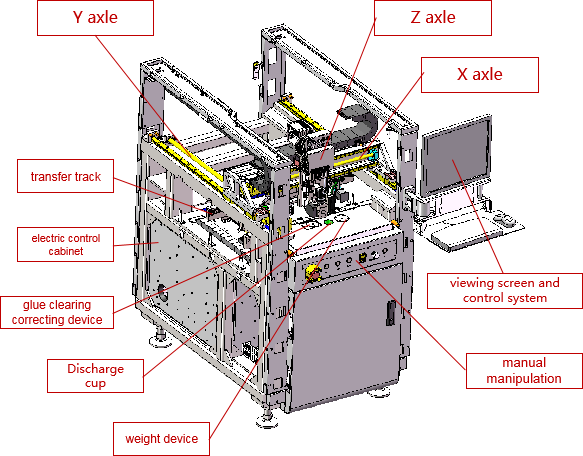

Interior Structure

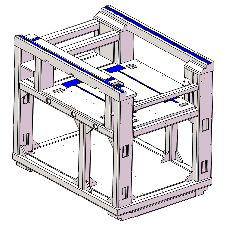

LongMen activity Support Structures

LongMen activity Support Structures is welded by high temperature annealing treatment to ensure normally to run without deforming,The machined mounting surfacewith high precision.

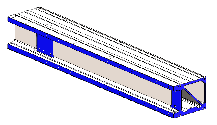

Integral stretch form beam

Integral stretch form beam forming,The mounting surface is finished by CNC machining center,The machined mounting surfacewith high precision .Ensure the high rigidity, stability and consistency of the equipment,the limiting displacement of beam use the worm-type supporting base with dovetail groove design ,So that it has a high applicability and convenience.

Advantages of modular design

1.Easy to assemble and maintain

2.Convenient expansion function

3.Modular fittings are standardized.

Function Module

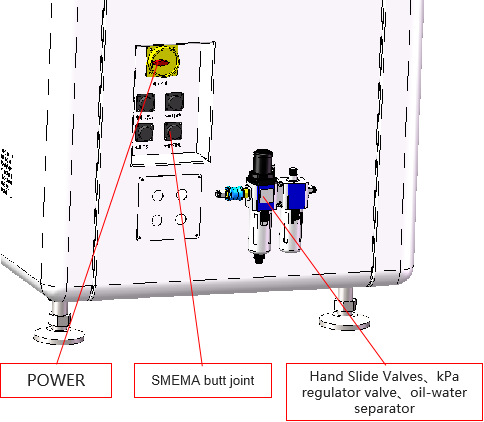

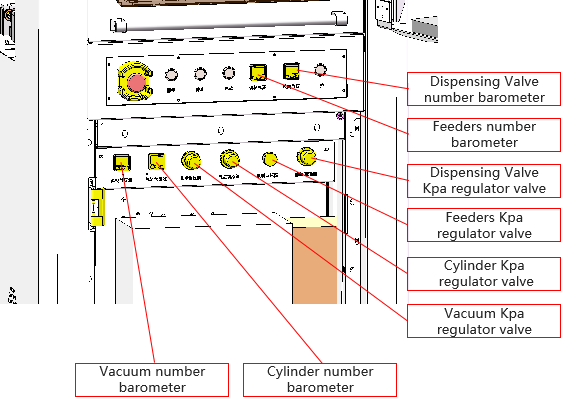

Equipment signal butt joint and electric interface

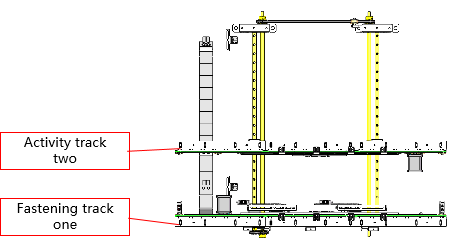

One track device(Standard Configuration)

Explanation

One track device:Track one is fastening track,unadjustable;Track two is activity track,electric adjustable the width,adjustable range:60mm~475mm

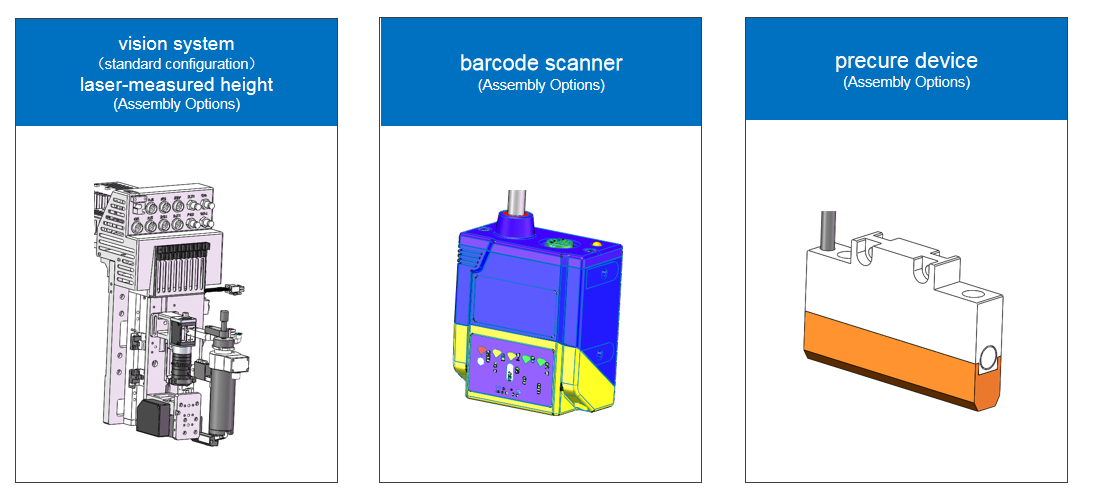

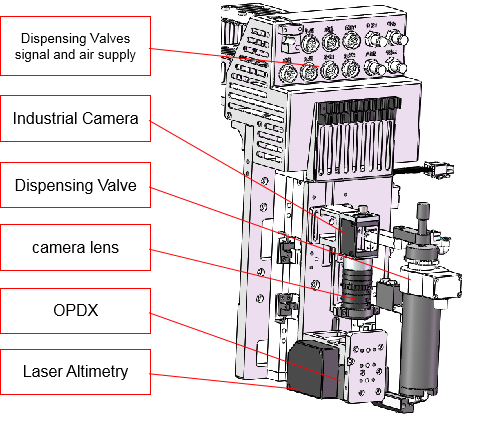

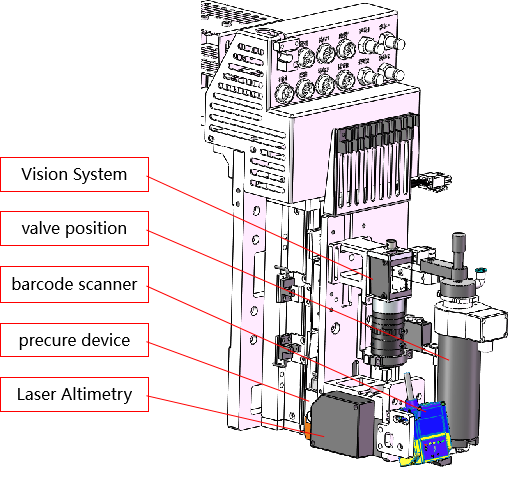

Vision System(Standard Configuration) Laser Altimetry(Assembly Options)

Explanation

1.Vision System:300000 pixels Industrial camera;Support electronic component recognition dispensing;automation MARK position fixing; Can capture contour for programming;You can configure a higher pixel camera;support catch on fly,Improve recognition speed.

2.OPDX,three colors light,improve the reliability of identification in different environments.

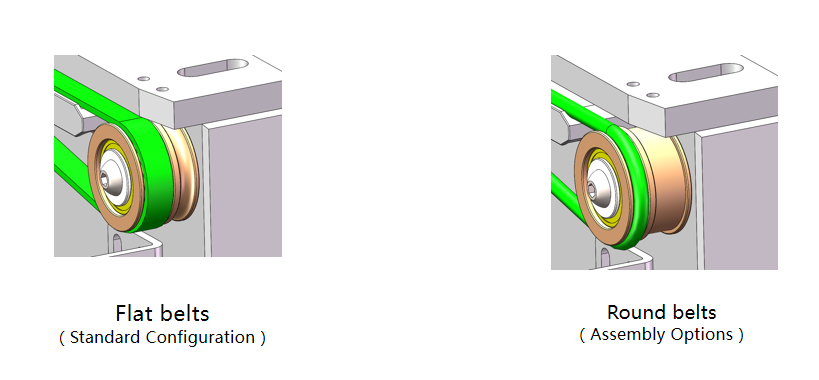

Flat belts(Standard Configuration) Round belts(Assembly Options)

Explanation

Conveyor belt match Flat belts or Round belts,just need change belt,don't need extra spare parts(Round belts is suitable for products with light weight and thin thickness).

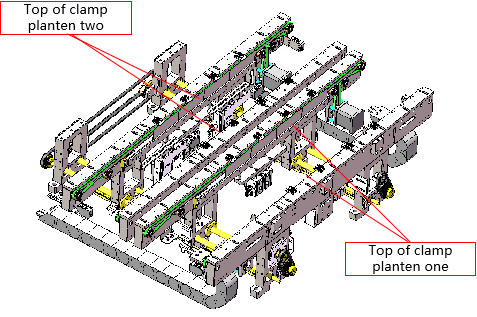

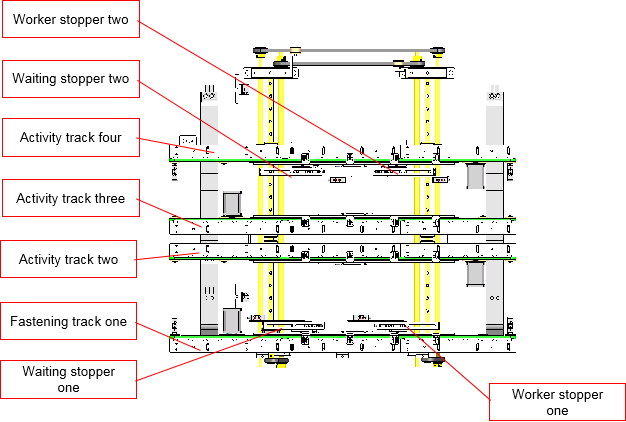

Assembly Options——double track decive

1.Track one is the fastening track ,unadjustable;Track two is activity track,electric adjustable the width;Track three is the activity track,And track two fixation,it can be electric adjustable with track two together;Track four is activity track,electric adjustable the width,adjustable range:60mm~405mm.

2.Stopper and top of clamp planten can be moved with the activity track,replacement of product specifications without manual removal to adjust the width.

3.segment clamp planten,can applicable to more product specifications.

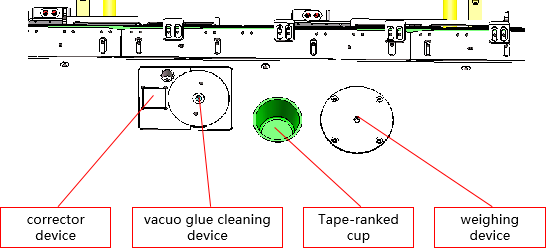

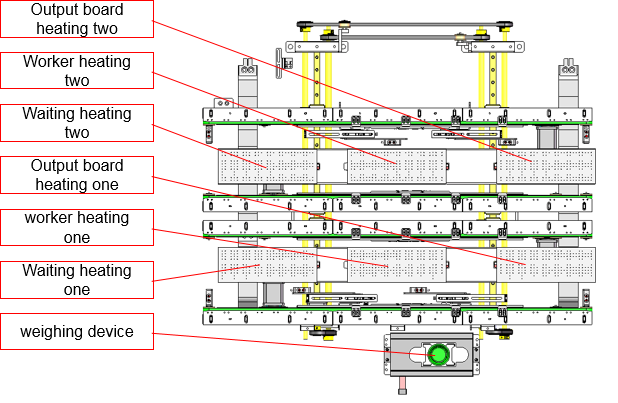

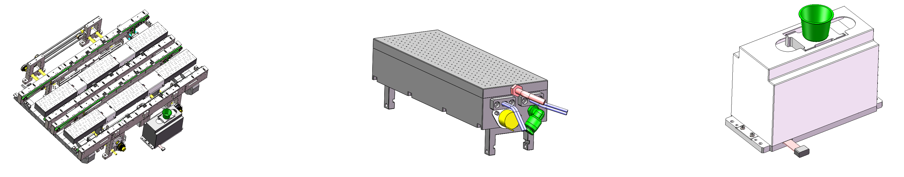

Assembly Options——heating device and precision weight device

1.Waiting heating,worker heating and output board heating,At most you can choose three-zone fired furnace,the subsection heating zone can be disassembled and supplemented at will;

2.The width of standard heating module is 50mm,70mm,90mm,you can freely combine it,Every heating module can control temperature independent,and control the temperature in±5 ℃.

3.Every heating device use the worm-type supporting base with dovetail groove design ,it’s can slide any position that needs heating.

4.the precision weight devece install on glueamount calibration system,can communication with software.

5.Software control the glueamount,Provide Closed-loop control,avoid manual adjustment.

6.You can choose the precision of weight device:0.1mg,0.01mg.

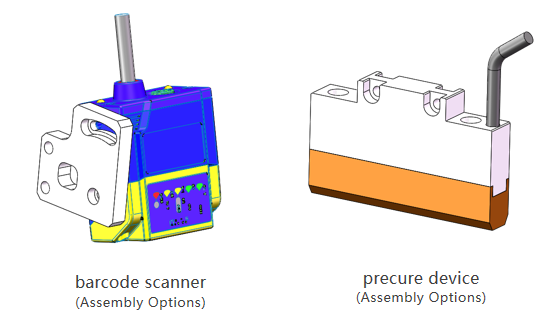

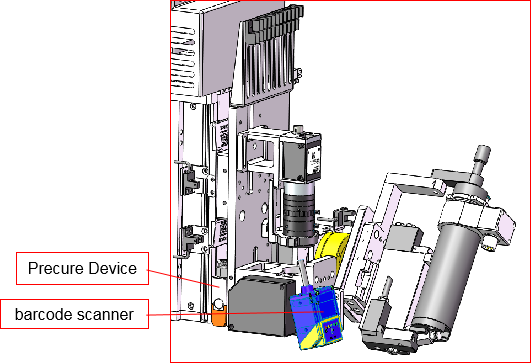

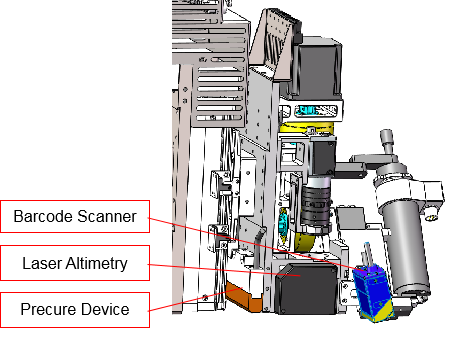

Assembly Options—barcode scanner and precure device

1,Standard configuration:vision system.Assembly Options:barcode scanne,precure device,Laser Altimetry.

2,Barcode scanner angleadjustable ±15°.

3,Precure device light source standard width is 10mm,length is 80mm;The length of the light source can be adjusted according to the actual use requirements;

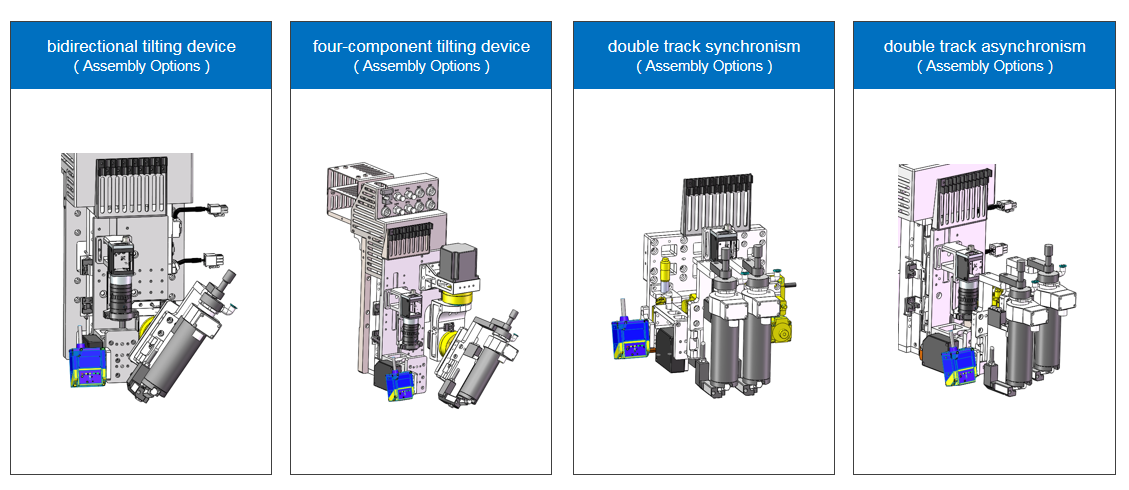

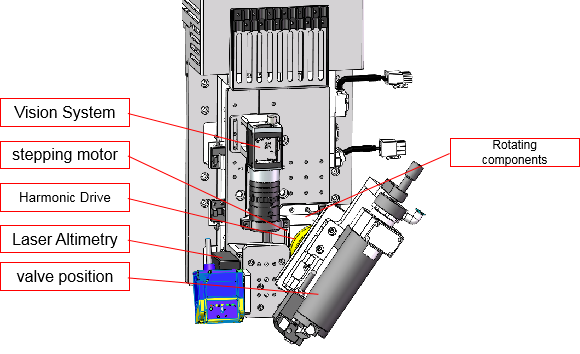

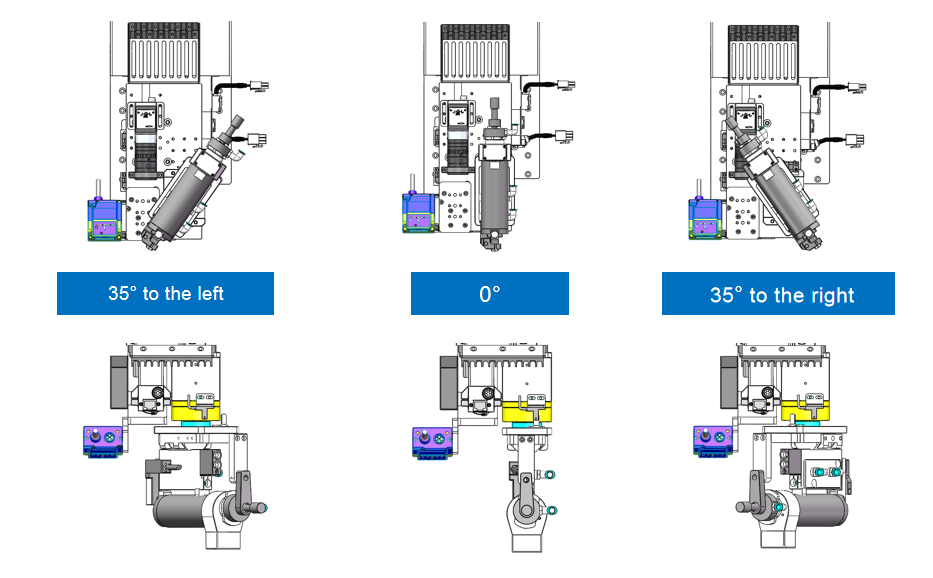

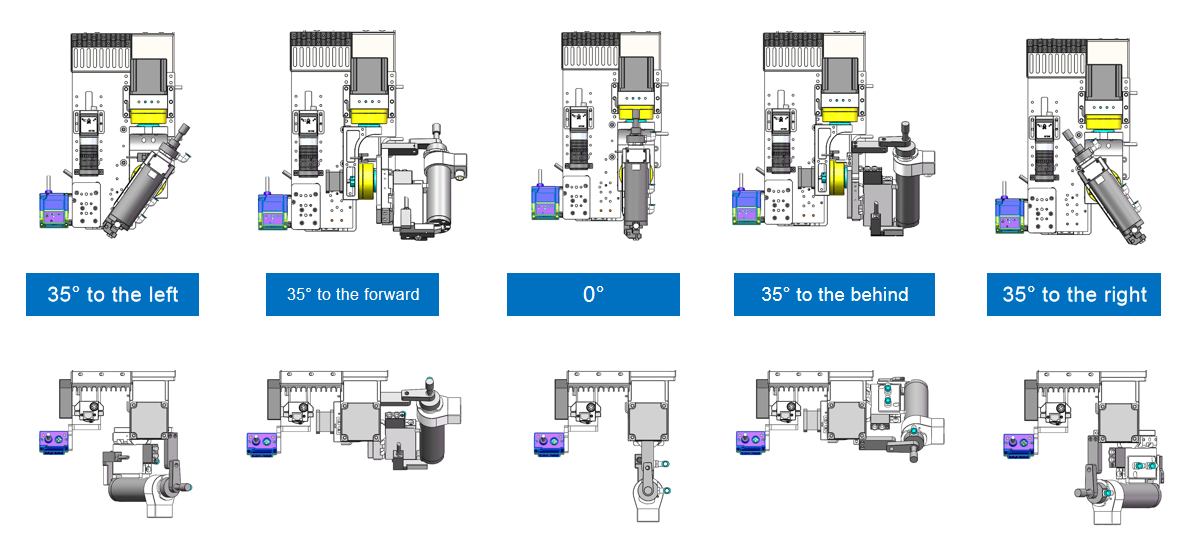

Assembly Options—bidirectional tilting device

Explanation

1,Stepping motor+Harmonic Drive,the dispensing valve is rotated by rotating the module,Solve the traditional dispensing valve rotation rigidity and accuracy of the problem.

2,Rotation angle±35°.

3,Standard configuration:vision system;Assembly Options:barcode scanne,precure device,Laser Altimetry;

Assembly Options—Two-way tilt

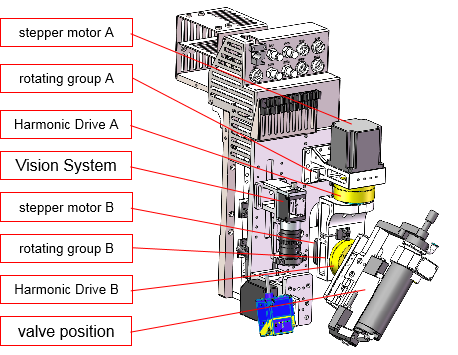

Assembly Options—four-component tilting device

Explanation

1,Stepping motor+Harmonic Drive, the dispensing valve is rotated by rotating the module,Solve the traditional dispensing valve rotation rigidity and accuracy of the problem.

2,A rotation angle:0°~90°,B rotation angle:0°~45°.

3,Standard configuration:vision system;Assembly Options:barcode scanne,precure device,Laser Altimetry;

Assembly Options—Four-way tilt

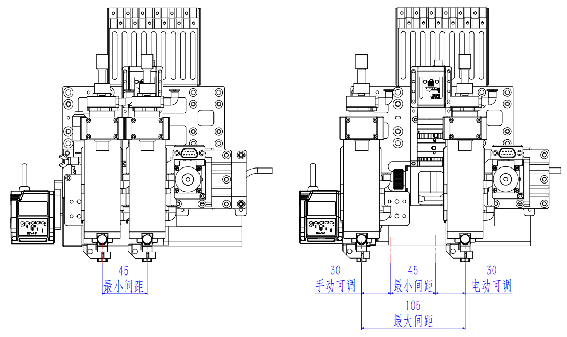

Assembly Options—double valve synchronism

1,the minimum distance of the wo dispensing valves is 45mm,the maximum is 105mm.

2,Z axle micrometer head can Manually correct the height of main valve in ±4mm,Y axle can electric correction the position of secondary valve in ±6mm,X axle can electric correction the width of the secondary valve in 30mm,manual the width of the secondary valve in 30mm.

3,Go through the track to complete two products dispensing, Productivity will be greatly increased.

4,Pass adjust main valve in Z axle,adjust secondary valve in X/Yaxle,Solve the problem of insufficient precision of traditional double valve operation.

5,Standard configuration:vision system;Assembly Options:barcode scanne,precure device,Laser Altimetry;

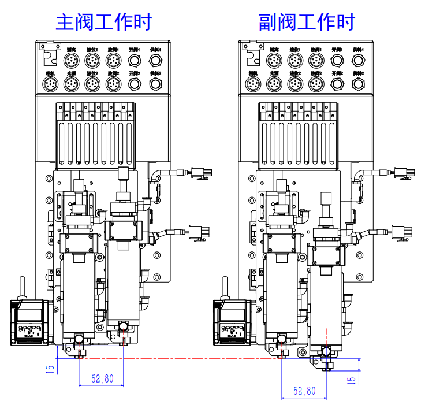

Assembly Options—double valve asynchronism

1,It is applicable to which product needs two different glue,First the main valve finished glue A,then secondary valve finished glue B;

2,Standard configuration:vision system;Assembly Options:barcode scanne,precure device,Laser Altimetry;

Double lifting,Pallet conveyor and collecting plate equipment.

Email: caojun@hk-yush.com / evaliu@hk-yush.com