1. Image and optical path system

The new optical path system--uniform ring light and high-brightness coaxial light, together with the brightness function that can be adjusted steplessly, makes all types of Mark points (including uneven Mark points) can be well identified. Tin-plated, copper-plated, gold-plated, tin-sprayed, FPC and other types of PCBs with different colors. YSL's patented mathematical operation model ensures that the machine can achieve high-precision alignment and can achieve 01005 printing.

2. Simple and easy-to-use humanized Chinese/English operation interface

Using windows XP operation interface, it has good man-machine dialogue function; especially in the navigation effect of program files, it is convenient for all operators to quickly familiarize with the operation; menu type Chinese/English switching, operation log, fault record/fault self-diagnosis/fault analysis Prompt/light alarm and other functions make the operation simple and convenient.

3. High adaptability steel mesh frame clamping system

Realize the printing of various sizes of screen frames, and can realize the rapid replacement of models in the production process.

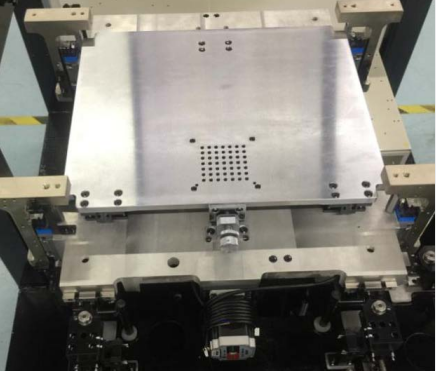

4. YSL special adjustment jacking platform

5. Cleaning system

The system provides three cleaning methods: dry cleaning, wet cleaning and vacuum cleaning. These three methods can be used in any combination, and when the customer does not need automatic cleaning, manual cleaning can be realized under the production interface, thereby reducing cleaning time and improving production. efficiency. The new wiping system ensures full contact with the steel mesh, and the large vacuum suction ensures that the residual solder paste in the mesh can be vigorously eliminated, and an effective automatic cleaning function is truly realized. The CCD part and the cleaning part are separated, when the CCD works, the CCD part moves independently, which reduces the load of the servo motor and improves the movement speed and precision of the machine.

6. 2D solder paste printing quality inspection and analysis

It can quickly detect printing problems such as offset, less tin, missing printing, and continuous tin to ensure printing quality

| The standard configuration | YSL-G5 Technical parameters and specifications | ||

| Model | YSL-G5 | ||

| Mask | Mask Min.Size(mm) | 370*370mm | |

| Mask Max.Size(mm) | 737*737mm | ||

| Mask Clamping | Air Cylinder | ||

| PCB | PCB Min.Size(LxW mm) | 50*50mm | |

| PCB Max.Size(LxW mm) | 400*340mm | ||

| Thickness(mm) | 0.4~6mm | ||

| Max.Weight | 3kg | ||

| PCB Under Clearrance | 15mm | ||

| PCB Clamping Type | Unique top flattening (auto retractable top crimping)/flexible side clamps/platform vacuum | ||

| PCB Support | Magnetic Thimble/Contour Block/ | ||

| Self-adjusting jacking platform | |||

| Conveyor | Conveyor Stage | One-section transport rail | |

| Transport Direction | left-right / right-left / | ||

| left-left / right-right | |||

| Conveyor width adjustment | automatic | ||

| Squeegee | Squeegee Type | Plastic scraper/steel scraper (angle 45°/ 55°/ 60°), user defined | |

| Auto.Pressure Control | 0.5~10Kg | ||

| Length | L=280,user-defined | ||

| Speed | 10~200mm/sec | ||

| Moving Direction | Move in the Y-axis direction | ||

| Accuracy | Repeated Accuracy | ±0.01mm | |

| Printing Accuracy | ±0.025mm | ||

| Printing time | Cycle Time(Excluding Printing and Cleaning time) | <8sec | |

| Fiducial Mark | Type | Standard shape reference point | |

| Size | 0.5~4mm | ||

| Mark Number | 2 or 4 marks | ||

| datum point positioning system | |||

| Mark Searching | automatic | ||

| Separation | Separation Type | normal/vacuum | |

| Speed | 0~20mm/s | ||

| Distance | 0~20mm | ||

| Cleaning System | Cleaning Type | Enhanced vacuum adsorption; three modes of dry, wet and vacuum; | |

| Cleaning Head | Wear resistant material | ||

| Moving Direction | Move in the Y-axis direction | ||

| Product Changing Time | Product changeover | <3 mins | |

| New Product Set up | <5 mins | ||

| Other | Operation System | Windows XP /Win7 | |

| Air Supply | 4~6 Kgf/cm2 | ||

| Power Supply | AC:220±10%, | ||

| 50/60HZ,2.5KW | |||

| Weight | 1000Kg | ||

| Single Size(LxWxH mm) | 1158(L)*1362(W)*1463(H) | ||

| 2D Inspection | Splicing Size(mm) | / | |

| FOV Camera | 8*6mm | ||

| Inspection | Less tin or missing and continuous tin | ||

| Inspection Size | 0.3mm or more | ||

| Max.Teaching Windows | Up to 500 screens can be displayed | ||

| YSL-G5 List of main parts of automatic solder paste printing machine | ||||

| Machine parts | Name | Brand | Quantity | Note |

| Z-axis lift section | Precision Ball Screw | Kuroda/Japan | 1 set | |

| Linear slide | HIWIN/Taiwan | 2 sets | ||

| Servo motor + driver | Panasonic/Japan | 1 set | ||

| photoelectric sensor | OMRON/Japan | 2 | ||

| Platform Correction Section | Linear slide | IKO/Japan | 9 sets | |

| Linear Motor | Haydon/USA | 3 sets | ||

| photoelectric sensor | OMRON/Japan | 8 | ||

| PCB Transport and holding parts | Precision Ball Screw | GTEN/Taiwan | 1 set | |

| Linear slide | HIWIN/Taiwan | 10 sets | ||

| Linear slide | CSK/Taiwan | 2 sets | ||

| stepper motor | Shinano/Japan | 3 sets | ||

| photoelectric sensor | Autonics/Korea | 2 | ||

| CCD Vision Section | Precision Ball Screw--X Axis | Kuroda/Japan | 1 set | |

| Precision Ball Screw--Y Axis | Kuroda/Japan | 1 set | ||

| Linear slide--X axis | INA/Germany | 1 set | ||

| Linear slide--Y axis | INA/Germany | 2 sets | ||

| Servo motor + driver | Panasonic/Japan | 2 sets | ||

| CCD camera | CIS/Japan | 1 set | ||

| photoelectric sensor | Opus/Japan | 2 | ||

| photoelectric sensor | OMRON/Japan | 4 | ||

| Scraper part | Precision Ball Screw | GTEN/Taiwan | 2 sets | |

| Linear slide | HIWIN/Taiwan | 6 sets | ||

| Servo motor + driver | Aiweitu/China | 1 set | ||

| Stepper Motor + Driver | Shinano/Japan | 2 sets | ||

| photoelectric sensor | OMRON/Japan | 4 | ||

| Fixed part of screen frame | Linear slide | HIWIN/Taiwan | 1 set | |

| cylinder | SMC/Japan | 6 pieces | ||

| photoelectric sensor | Autonics/Korea | 1 | ||

| Cleaning part | Roll paper motor + driver | DINGS/China | 1 set | |

| Drip motor + driver | Shinano/Japan | 1 set | ||

| Linear slide | HIWIN/Taiwan | 1 set | ||

| photoelectric sensor | OMRON/Japan | 4 pieces | ||

| Industrial computer | Advantech/Taiwan | 1 set | ||

| Control section | motion control card | Lei Sai/China | 3 sets | |

| LCD color display | DELL/USA | 1 set | 17 inches | |

| mouse | colorful/china | 1 | ||

| keyboard | Wallaby/China | 1 | ||

| hand press | Izumi/Japan | 5 | ||

| Other | bearing | NSK/Japan | All | |

| flexible cable | IGUS/Germany | |||

Email: caojun@hk-yush.com / evaliu@hk-yush.com