Features:

1. Independent research and development of electromagnetic pump

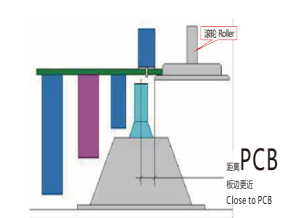

2. Chain and roller hybrid transmission system

3. Automatic track width adjustment system

4. High precision spray nozzle

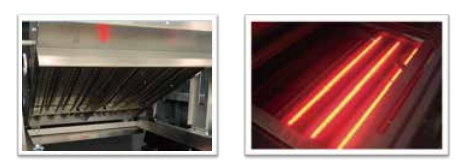

5. Bottom infrared preheating

6. Top hot air preheating

7. Support online/offline programming, easy programming

8. Can be welded on both sides of PCB

9. Welding parameters can be set independently for each solder joint

10. Display the welding status in the whole process

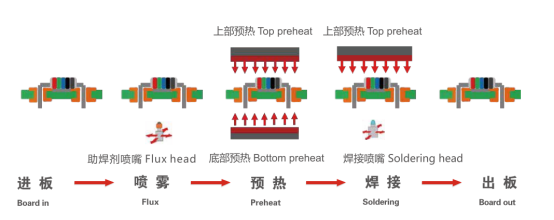

Standard machine basic structure module:

1. Spray module

2. Preheating the module

3. Welding module

4. Transmission system

Basic working principle: After the spray head controls the PCB board to move to the designated position according to the pre-programmed program, it only sprays flux on the parts that need to be soldered. After spraying and preheating, the electromagnetic pump platform drives the electromagnetic pump to move to the designated position according to the preset program. The parts that need to be welded are then welded.

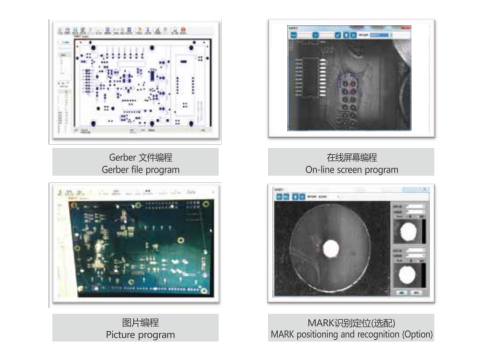

Fast and convenient programming system

Features and advantages:

1. Three programming methods to choose from

2. Support offline programming

3. Different welding parameters are available for each welding point

4. Process data recording

Technical parameter

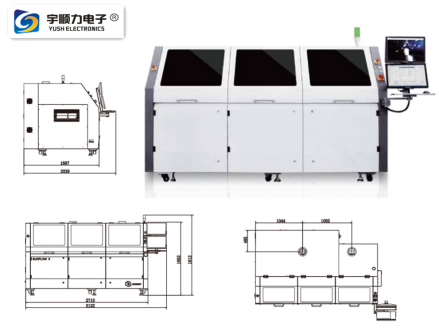

| Parameters | Name | Specification |

| Body parameters | Device Dimensions | 2710(L)*1670(W)*1630(H) |

| Equipment weight (KG) | 2000 | |

| Maximum PCB board size | 510(L)*450(W) | |

| Minimum PCB board size | 120(L)*50(W) | |

| PCB top clearance | 120 | |

| PCB bottom clearance | 60 | |

| PCB process side | ≥3 | |

| Conveyor belt height above ground | 900±20 | |

| PCB transfer speed | 0.2-10 | |

| PCB weight (KG) | ≤5 | |

| PCB thickness (including fixture) | January 6 | |

| Adjustable range of conveyor belt | 50-450 | |

| Conveyor belt width adjustment method | Electric | |

| PCB transfer direction | Left to right | |

| Air intake pressure | 0.6 | |

| Nitrogen supply | Provided by customer | |

| Nitrogen inlet pressure | 0.6 | |

| Nitrogen consumption | 1.5 | |

| Required nitrogen purity | >99.999 | |

| Voltage | 380 | |

| Frequency | 50/60 | |

| Maximum power consumption | <28 | |

| Maximum current | <56 | |

| Ambient temperature | ||

| Machine noise | <65 | |

| Communication Interface | SMEMA | |

| Welding system | Welding X-axis maximum travel | 510 |

| Maximum travel of welding Y axis | 450 | |

| Welding Z axis maximum travel | 60 | |

| Minimum Nozzle Outer Diameter | 5.5 | |

| Nozzle inner diameter | 2.5-10 | |

| Maximum crest height | 5 | |

| Tin furnace capacity | Approx.13kg(Sn63Pb)/ Approx.12kg(lead-free) | |

| Maximum Soldering Temperature | 330 | |

| Tin furnace heating power | 1.15 | |

| Preheating system | Preheat temperature range | <200 |

| Heating power | 24 | |

| Heating method | Hot air + Infrared | |

| Top preheat | Hot air | |

| Spray system | Spray X-axis maximum travel | 510 |

| Maximum stroke of spray Y axis | 450 | |

| Spray height | 60 | |

| Positioning speed | <400 | |

| Nozzle automatic cleaning function | Program control | |

| Flux tank capacity | 2 |

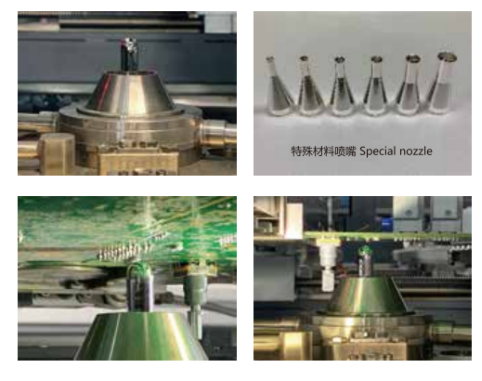

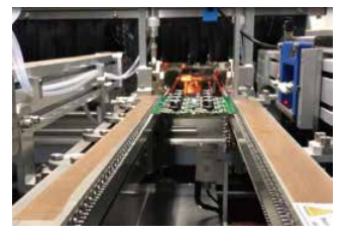

Stable and high quality welding------welding module

Features and advantages:

1. Independent research and development of electromagnetic pump

2. Stable crest height

3. Special material nozzle (can be used for 3 months)

4. The nozzle is easy to remove and replace

5. Very low maintenance rate

Using an electromagnetic pump, compared with a mechanical pump, the electromagnetic pump has stable wave peaks during operation, no mechanical wear of the movement, and produces very little waste. In addition, the welding module adopts a high-precision motion system to ensure the accuracy of the welding process. , The colleague cooperates with the special process, which can greatly eliminate the phenomenon of tin connection. In terms of user experience, it provides welding monitoring cameras and automatic detection of wave height, which greatly improves the user experience.

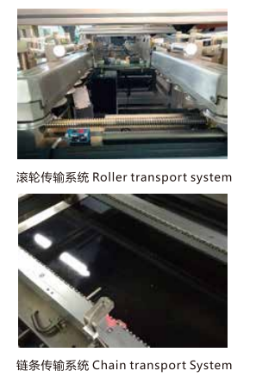

Transmission system

Integrated chain transmission system and roller transmission system. Among them, the reheating module and the spraying module are driven by chains. The welding module adopts roller drive, which can greatly improve the positioning accuracy and repeatability

Perfect preheating----preheating module

Combining upper and lower preheating is also perfect for lead-free soldering or multi-layer PCBs. The upper hot air preheating has been used in Nitto reflow soldering for many years, with stable performance, it can evenly disperse the heat on the PCB. The lower infrared preheating can open the preheating pipes in different areas according to the size of the PCB to save energy. At the same time, the welding module also provides the upper hot air preheating, which can ensure the preheating temperature during the whole welding process and guarantee the perfect performance of the flux.

selective soldering process

1. Transport the PCB to the spray module

2. The flux spray moves to the command position and selectively sprays the position that needs to be soldered

3. The upper hot air and the lower infrared module preheat the PCB

4. The electromagnetic pump is welded according to the programmed path

5. PCB outgoing

High precision spray---spray module

The standard machine adopts precision drop nozzle imported from Germany, the diameter of the nozzle is 130μm, which can evenly spray the flux on the required welding area. The minimum spray area is 3mm, saving at least 90% flux compared to traditional spray. According to user needs, in the case of low precision of spray area size, spray nozzles are also provided to make the spray process faster.

All module movements are driven by private clothes and ball screws, the movement process is smooth and stable, and the repeatability can reach 0.05mm.

Email: caojun@hk-yush.com / evaliu@hk-yush.com