10 LCD

Model No.

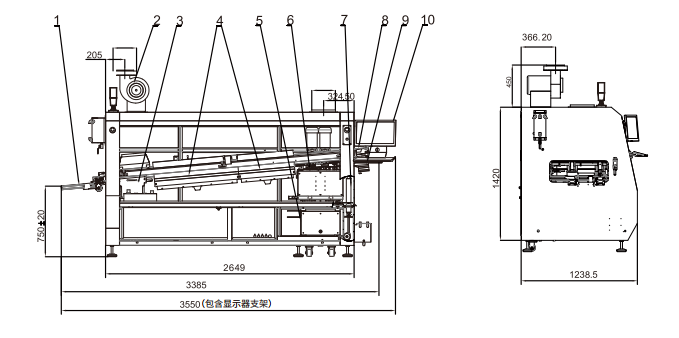

YSL-300E

YSL-320E

Dimension: L*W*H(mm)

3385*1240*1540

3385*1190*1540

Weight

Approx.1150kg

Approx.1100kg

Power Supply

3PH 380V 50HZ

3PH 380V 50HZ

Start up Power

28KW

27KW

Normal Running Power

7KW

6.7KW

Control System

PC+PLC

Spraying movement

Step motor

Spraying Pressure

0.2Mpa~0.4Mpa

Flux Flow Control

Option

Auto Flux Filling

Standard

Exhausting

Top exhaust

/

Exhausting Pipe Diameter(mm)

Φ250

Exhaust fan power

370W

/

Preheating Mode

IR

Temperature Control Mode

PID

Preheating Zone Quantity

2

Preheating Zone Length(mm)

1500

Preheating Temperature Range

Room temperature~200℃

Warm-up Time(min)

Approx.12min(setting: 150℃)

Width(mm)

50~300

PCB Conveying Direction

L→R( Option:R→L)

Conveying Speed(mm/min)

500~1800

Conveying Height(mm)

750±20

Available Component Height(mm)

Top120 Bottom15

Conveying Speed Control Mode

Closed loop stepless speed regulation by inverter

Finger

Spring Pressing Finger;D-40 Type Finger;Double-hook Finger;Heavy type double hook finger(Options)

Conveying Angle

4~6°

Solder Pot Type

Mechanical

Solder Pot Material

Casting Iron material

Wave Height Adjustment

Digital Control by PC

Cooling type

Air cooling

/

Solder Pot Heating Power

9KW

220V 9KW

Max Solder Pot Temperature

300℃

Solder Pot Capacity

Approx.350kg

Wave Driving Power

180W*2 3PH 220 VAC

Solder Pot Warm-up Time

Approx.150min(setting: 250℃)

Temperature Control Mode

PID

Finger Cleaning System

Brush

/

Email: caojun@hk-yush.com / evaliu@hk-yush.com