High efficiency Integrated selective wave soldering for SMT production line

Discription:

|

Specification items |

YS-320Y/ YS-320YT |

|

Applicable PCB board size |

L*W : 50×50~320×250 mm |

|

Applicable PCB board thickness |

Substrate thickness:0.8~3 mm / Pin length:3mm 以内 |

|

Component height |

Less than 100mm above the substrate / Less than 50mm below the substrate |

|

Substrate shape and conditions |

1. Substrate placement edge: more than 3mm from the substrate process edge. \ n2. The weight including components is 5KG The following 3. Substrate bending: less than 0.5mm |

|

Tin furnace |

Tin furnace material/capacity: All-titanium alloy material / 12KG Tin bath capacity: Power: 4*500W, 2KW |

|

Preheating power |

Infrared preheating 1KW |

|

Total power |

AC 220V 3.5KW |

|

N2 Requirements |

Nitrogen purity:99.999% Pressure/Consumption:0.5MPa / 20ℓ/min~30ℓ/min / 1.2 cubic meters |

|

Flux nozzle |

0.5mm precision fluid nozzle imported from Japan |

|

Flux capacity |

2 L |

|

Gas source |

0.5-0.7Mpa |

|

Nozzle inner diameter |

φ 3mm~φ 20mm Customizable size |

|

Peak height |

Automatic alignment/height measurement |

|

System control |

PC+PLC(windows+Huichuan) |

|

Programming software |

Support programming for online or offline image production |

|

Video surveillance |

Real-time video monitoring makes it convenient to watch the welding effect |

|

Power supply/power |

Single-phase 220V±10 Starting power:3.5KW |

|

Weight |

120KG (Containing solder12KG) |

|

YS-320YExternal dimensions |

L*W*H 910×980×1350 mm (With a display) |

|

YS-320YTExternal dimensions |

L*W*H 910×980×1500 mm (Including the upper cover) |

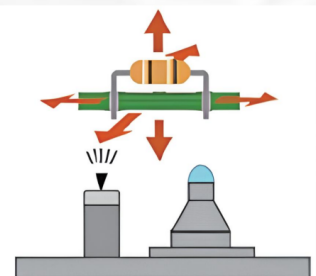

Solve the difficulties in DIP welding

Selective wave soldering working mode

During offline selective welding,

The welding nozzle is fixed.

The PCB board is set

Move in the X,Y, and Z axes to achieve

the soldering of PCB solder joints.

Selective spraying

Advantage

It can maintain the original packaging

performance of the flux The dosage is controllable and repeatable

The dosage is very low. Strong process reliability

No solvent needs to be added The flux was fully utilized and there was no waste

Email: caojun@hk-yush.com / evaliu@hk-yush.com