High efficiency Integrated selective wave soldering for SMT production line

Discription:

|

Specification items |

YS-450Y / YS-450YT |

|

Applicable PCB board size |

L*W : 50×50~450×400 mm |

|

Applicable PCB board thickness |

Substrate thickness:0.8~3 mm / Pin length:Within 3mm |

|

Component height |

Less than 100mm above the substrate / Less than 50mm below the substrate |

|

Substrate shape and conditions |

1.Substrate placement edge: more than 3mm from the substrate process edge 2.The weight including components is less than 5 kilograms 3.The bending of the substrate: less than 0.5mm |

|

Tin furnace |

Tin furnace material/capacity:All-titanium alloy material/15KG Tin bath capacity:Power:4*500W2KW |

|

Preheating power |

Infrared preheating 1KW |

|

Total power |

AC 220V 3.5KW |

|

N2 Requirements |

Nitrogen purity:99.999% Pressure/Consumption:0.5MPa / 20ℓ/min~30ℓ/min / 1.2 cubic meters |

|

Flux nozzle |

0.5mm Precision fluid nozzles imported from Japan |

|

Flux capacity |

2 L |

|

Gas source |

0.5-0.7Mpa |

|

Nozzle inner diameter |

φ 3mm~φ 20mm Customizable size |

|

Peak height |

Automatic alignment/height measurement |

|

System control |

PC+PLC(windows+汇川) |

|

Programming software |

Support programming for picture line drawing (convenient and fast) |

|

Video surveillance |

Real-time video monitoring makes it convenient to watch the welding effect |

|

Power supply/power |

Single-phase 220V±10% Starting power:3.5KW |

|

Weight |

150KG (Containing solder12KG) |

|

External dimensionsSW-450Y |

L*W*H 940×1280×1350 mm (With a display) |

|

External dimensionsSW-450YT |

L*W*H 1110×1280×1500 mm (It does not include three-color lights) |

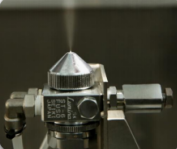

Selective spraying

Fogging effect (shot in strong light) Linear spray (optional)

Original 0.5mm "Lumina" imported from Japan

Precision fluid nozzle

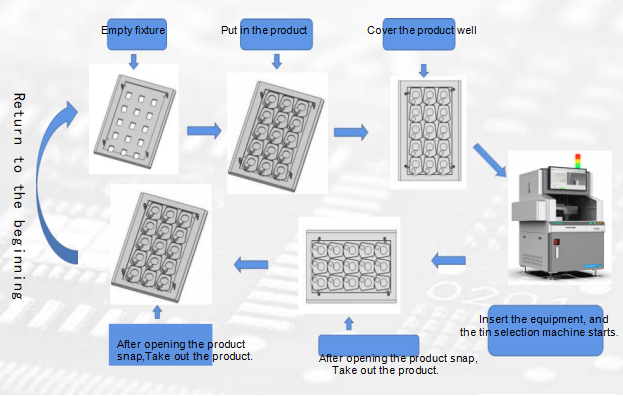

Operation process

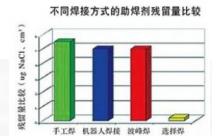

Comparison of conventional production equipment

Project

Ordinary wave soldering

Soldering iron robot

Selective welding machine

1

Production application scope

Mass production/conventional process

Small-batch welding/simple process

Small batch/multiple models The welding quality requirements are high

2

Multilayer circuit

boardThrough-hole tin permeability

50%

80%

99.99%

3

Tin bath capacity

400-500kg

Soldering wire

12KG

4

The amount of solder slag produced in 8 hours

5~8 KG

0.5 KG

0.2 KG

5

Flux residue

6

Power consumption of working power supply

12 KW

1 KW

1 KW

Email: caojun@hk-yush.com / evaliu@hk-yush.com