High efficiency Split selective wave soldering machine YS-320S for SMT production line

Discription:

|

Specification items |

Split selective wave soldering SW-320S |

|

Applicable PCB board size |

L*W : 50×50~320×250 mm |

|

Applicable PCB board thickness |

Substrate thickness:0.8~3 mm / Pin length:Within 3mm |

|

Component height |

On the substrate Less than 100mm / Less than 30mm below the substrate |

|

Substrate shape and conditions |

1.Substrate placement edge:The edge of the substrate process is more than 3mm 2.The weight including components is less than 5 kilograms 3.The bending of the substrate: less than 0.5mm |

|

Tin furnace |

Tin furnace material/capacity: All-titanium alloy material / 12KG Tin bath capacity: Power: 4*500W, 2KW |

|

Preheating power |

Infrared preheating 1KW |

|

Total power |

AC 220V 3.5KW |

|

N2 Requirements |

Nitrogen purity:99.999% Pressure/Consumption :0.5MPa / 20ℓ/min~30ℓ/min / 1.2 cubic meters |

|

Nozzle inner diameter |

φ 3mm~φ 20mm Customizable size |

|

Peak height |

Automatic alignment/automatic height measurement |

|

System control |

PC+PLC(windows+Siemens) |

|

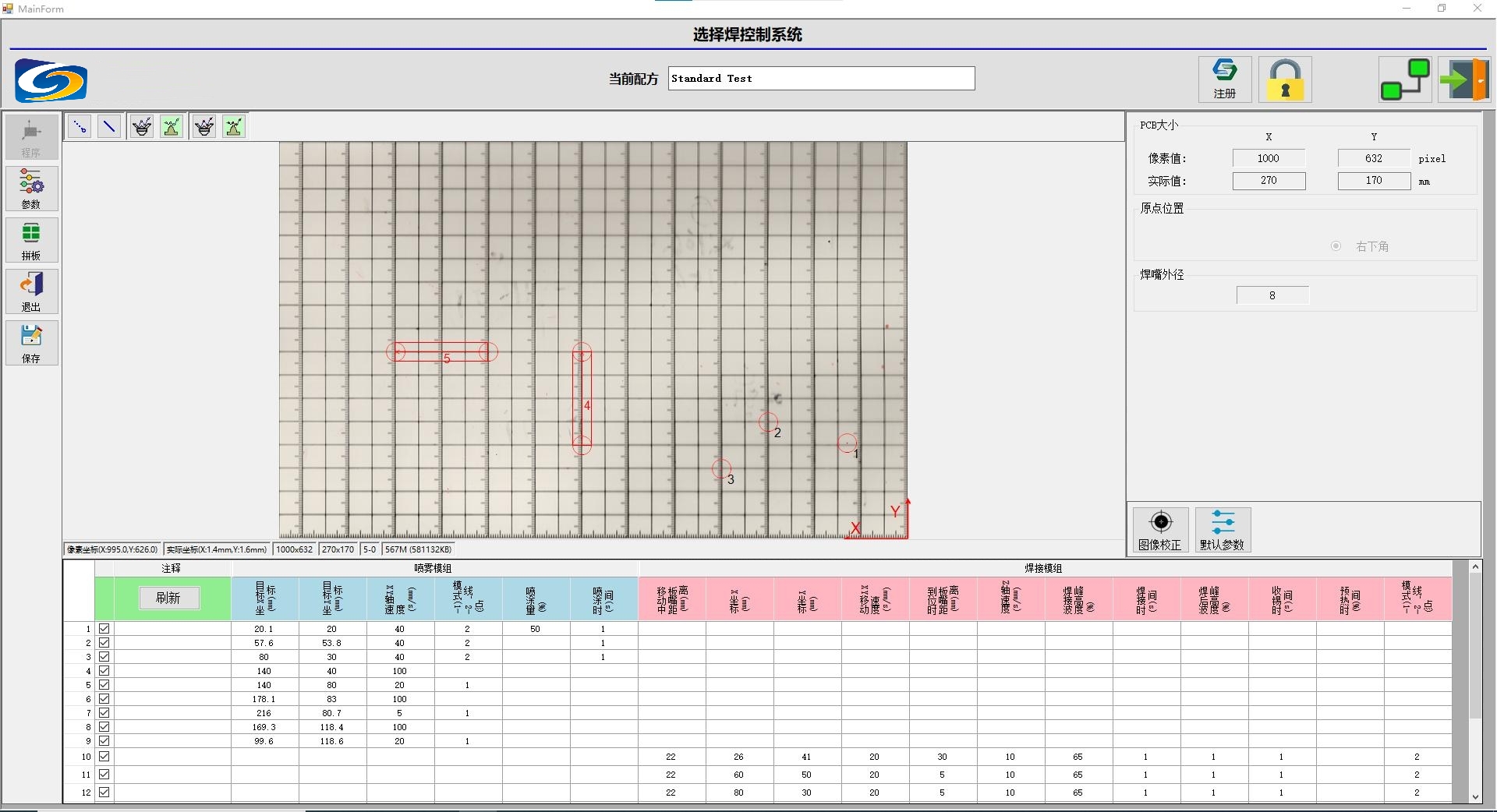

Programming software |

Support offline image production programming |

|

Power supply/power |

Single-phase 220V±10 Starting power:3.5KW |

|

Weight |

100KG (Containing solder12KG) |

|

External dimensions |

L*W*H 750×820×1350 mm (It does not include three-color lights) |

Automatic detection of wave peak height Real-time video monitoring of wave peaks and welding status

ensures the stability of wave peaks and

improves the welding yield.

Program programming

It is intuitive, convenient and fast to import PCB board pictures for programming. It can be programmed offline on an office computer

and then imported into the device for use, quickly integrating into production

List of key components

Serial number

Name

Brand

Remarks

1

Tin furnace

Titanium alloy

2

PLC

Huichuan

3

Temperature control

Yamabu, Japan

4

Thyristor

Swiss Jiale, Taiwan Yangming

5

Spray

Lumina, Japan

6

Pneumatic component

SMC of Japan and Aideke of Taiwan

7

Lead screw, track

TaiwanPMI

8

Wave Peak Motor

200-degree customized high-temperature motor

It operates at a constant temperature of 200 degrees for a long time

9

Air switch

Schneider

10

Relay

Songchuan, Taiwan

11

Button

APT Siemens

12

Power supply

Mingwei, Taiwan

13

Computer

Industrial control computer

14

Display

AOC

Email: caojun@hk-yush.com / evaliu@hk-yush.com