High quality Split selective sprayer YS-320F for SMT production line

Discription:

Specification items

Split-type selective sprayer YS-320F

Applicable substrate size

L*W : 50×50~320×250 mm

Applicable substrate thickness

0.8~3.0 mm

Component height

Less than 100mm above the substrate / Less than 35mm below the substrate

Substrate shape and conditions

1.Substrate placement edge: more than 3mm from the substrate process edge

2.The weight including components is less than 5 kilograms

3.Substrate bending: less than half of the substrate thickness

Flux nozzle

0.5mm "Lumina" precision fluid nozzles imported from Japan

Flux capacity

1 L

The applicable range of flux

Substrate process edge:3mm

The welded components are away from the edge of the base plate:5mm

System control

PC+SiemensPLC

Programming software

Support online or offline image programming

Work pressure

0.5-0.7Mpa

Power supply/power

Single-phase 220V±10% 500W

Weight

60KG

External dimensions

L*W*H 750×900× 850mm (It does not include three-color lights)

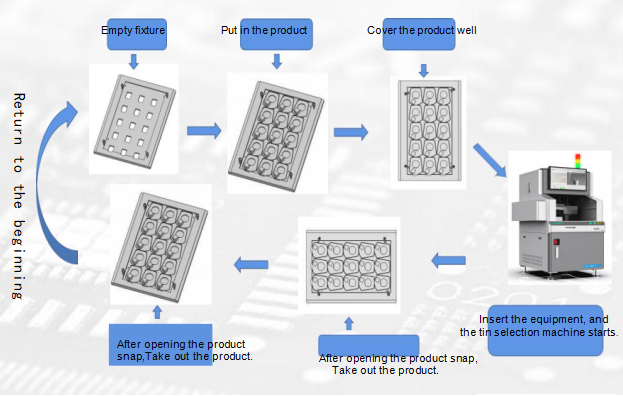

Operation process

Costomer usage site

Comparison of online and offline selection welding

Project

Online selective wave soldering

Offline selective welding machine

1

Production scope

Small batch/multiple models The welding quality requirements are high

Small batch/multiple modelsThe welding quality requirements are high

Applicable to the needs of different customers

Production scope

Small batch/multiple models The welding quality requirements are high

Small batch/multiple modelsThe welding quality requirements are high

The personnel required for online and offline are the same

Depending on the product, it takes 1.5 to 2.5 seconds for single-cylinder or double-cylinder

Depending on the product, it takes 1.5 to 2.5 seconds for single-cylinder or double-cylinder

Depending on the product, the welding efficiency can be improved in a 1+N manner within 1.5 to 2.5 seconds, with 1 spray followed by 1 or 2, 3 welds

The off-line type can be used for those with many solder joints

PCB board, can be soldered in 1+N mode

The connection efficiency is higher than that of the online machine

Equipment cost

High input cost

Low input cost and strong flexibility

The input cost of the offline type has a significant advantage potential

2

3

4

Email: caojun@hk-yush.com / evaliu@hk-yush.com