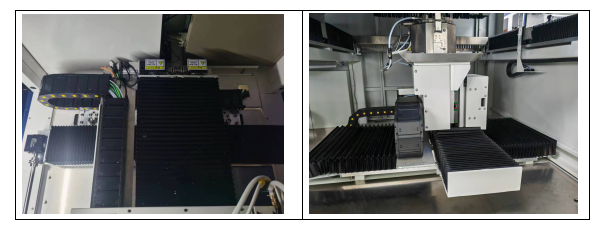

High quality Single-head online three-stage selective wave soldering For SMT production line

Description:

specifications

Parameter

Overall Dimensions

2850L*1650W*1850H (mm)

Machine frame

Steel structure+baking paint

度Operating height

900±30mm

machine appearance

closed - type

PCB board transportation method

Spray preheating guide rail chain transportation, welding roller transportation

Programming methods of programs

Picture programming, Gerber document, visual teaching programming, etc.

monitoring

standard configuration

Weight

Approx.1500KG

Power supply

380V Three-phase five-wire system, 380V

Total power

30KW

Operating mode

PCB board guide transportation, XYZ axis movement of solder pot, XYZ axis movement of flux spray valve.

PCB parameter

PCB size

Min:30(L)*30(W); Max:500(L)*500(W)(mm)

Adjustable width of guide rail

30-600mm

Thirty to six hundred millimeters

Guideway width adjustment method

Electric width adjustment

Top component height

Max120mm

Bottom component height

Max30mm

PCB Weight

Max20Kg

PCB Process Edge

>3mm

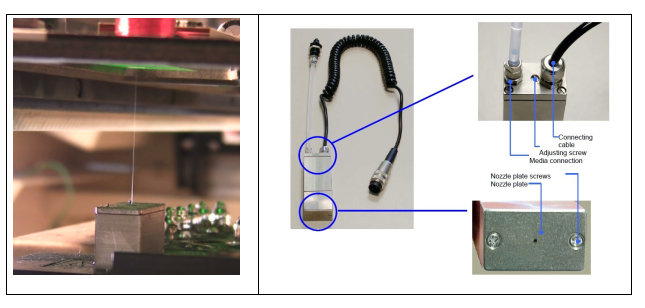

Selective spray system

Spray movement mode

The spray valve moves on the XY axis.

Mobile control mode

Servo motor + lead screw guide rail

Spray flux volume

one liter

Spray flux add mode

Manual

Spray nozzle type

Spot fire valve

Nozzle diameter

0.13mm

Spray cycle time

1 Sec/soldered dot(The minimum spray time can be set to 0.1 seconds)

Spray movement precision

±0.1mm

spray moving speed

Adjustable from 0 to 500 mm

Spray flow control

pulse controller

Preheating system

Preheating method

Heating from top and bottom

Heating form

Upper infrared heating, lower infrared spotlight heating

temperature control

Hot air setting temperature control, infrared heating rate ratio and time

Temperature control accuracy

±2

Selective Soldering System

Welding movement mode

The tin furnace moves along the XYZ axes

Movement mode

Servo motor + linear rail

Preheating compensation on the top of the solder pot

Hot air heating

Solder feeding mode

Manual

Number of soldering iron tips

one

Solder capacity

15KG

Solder melting time

45min

Solder power

1.2KW

Solder nozzle size

Standard with 5 solder tips (3-64-8 6-10 8-12 10-14)

Solder cycle time

1~5Sec/ soldered dot

Temperature control mode

PID+SSR

Temperature setting range

Max350OC

Temperature accuracy

±2OC

Waver height

Max 0-8mm

Welding precision

±0.1mm

Solder dross

0.2Kg/8H(Not N2 protection);0.01Kg/8H( N2 protection)

N2 protection system

N2 protection mode

Nozzle and solder pot

N2 consumption

1.5M3/h(Nitrogen concentration>99.999%)

N2 flow control

Glass rotor flowmeter

Exhaust system

Top cover exhaust

Customer supply

Exhaust quantity

2PCS

Exhaust vent diameter

150mm

Exhaust volume

About 15m³/h(Provided by the customer with an external exhaust channel)

Control system

Control mode

PC+ motion control card

PCB Process parameter

Setting, save , open in the PC screen

Other

PCB counting, message, alarm can be read in the PC

Common Wear & Tear Parts

Welding nozzle, nozzle cleaning fluid, high-temperature bearing

Standard machine include

|

Serial |

Item |

content |

Quantity |

|

1 |

Controlling system |

PC & monitor |

1set

|

|

Live on monitor camera |

|||

|

dual motion control |

|||

|

2 |

Motion table(fluxing) |

Fully cast iron xy motion table |

1set

|

|

2 axis equipped with ball screw & linear guild rail |

|||

|

2 axis equipped with servo motor & driver |

|||

|

3 |

Fluxing system |

Imported jet fluxing valve(dual nozzle) |

1set |

|

flux tank |

|||

|

flux pneumatic system |

|||

|

4 |

preheating system |

slight heat on the wind and preheating with infrared spotlights |

1set |

|

5 |

Motion table( soldering ) |

Fully cast iron xyz motion table |

1set |

|

3 axis equipped with ball screw & linear guild rail |

|||

|

3 axis equipped with servo motor & driver |

|||

|

6 |

Soldering pot |

13KG electromagnetic pump tin furnace |

1set |

|

solder temperature over heat alarm system |

|||

|

solder temperature controlling system |

|||

|

2 inline heating system |

|||

|

(inner diameter 8mm, 3mm, 4mm, 5mm,6mm )Standard equipped solder nozzle |

|||

|

7 |

Conveyor system |

stepper control for front & rear conveyor |

1set |

|

pin chain for conveyor (soldering section) |

|||

|

PCB Plate blocking device spray section, preheating section |

|||

|

stepper control for front & rear conveyor |

|||

|

roller for conveyor (soldering section) |

|||

|

PCB stopper system |

|||

|

PCB side clamping system |

|||

|

8 |

Machine chassis |

machine frame/cover & painting |

1set |

Motion system

Fluxing system

Standard equipped with imported jet valve to get precious fluxing result with small flux dot, please note flux solid content should be less than 10%.

Flux is stocked by PP plastic pressure tank, make sure pressure stable without influenced of amount of flux.

Machine key parameters

name

brand

brand belong

Controlling

industrial computer

Evoc

China

monitor

Philips

ned

Controller

positive motion

China

SSR

Jiale

Switzerland

box relay

Omron

Japan

switch

Mingwei

chinese taiwan

contactor

CHNT

China

AC contactor

Schneider Electric

France

sensor

Omron

Japan

Motion parts

Servo motor

Panasonic

Japan

servo driver

Panasonic

Japan

ball screw

SHANGYIN

Taiwan

linear guild

SHANG YIN

Taiwan

Pneumatic

Pressure sensor

AirTAC

chinese taiwan

Air cylinder

AirTAC

chinese taiwan

Email: caojun@hk-yush.com / evaliu@hk-yush.com