Product Description:

| PCB Routing Equipment Latest wholesale price | |

| Setting Fixture | 2 stations |

| Working Area | X:330mm, Y:330mm, Z:60mm |

| Cutting Area | Max:X:330mm, Y:330mm |

| PCB Component Height | Top side:15mm Bottom side:35mm(with universal jig),45mm(with specific jig) |

| PCB Thickness | 0.5 to 2.0 mm (It’s necessary to contact Aurotek in advance for over 2mm) |

| Router Bit Diameter | 0.8 ~ 2.0 mm(Option:Over 2.0mm) |

| Precision of Cutting | ± 0.08mm |

| Positioning Accuracy | ± 0.01mm |

| Positioning Repeatability | ± 0.02mm |

| Number of Axis in use | 4 Axis (X, YL, YR, Z). |

| Driving Speed (Max) | X, YL, YR : 1000mm/sec, Z: 750mm/sec |

| Cutting Speed (Max) | X, Y, Z: 100mm/sec (It's according to the specification of Bit for the best speed setting ) |

| Spindle Motor | High speed variable frequency motor 250W (Max.58,000rpm) |

| Bit Change | Manual |

| Cutting Ability | Linear, Circular, U-curve, Arc, L-curve |

| Motor of Axis | 4 Axes (200W AC Servo motors) |

| Bit Shift Count | Max. 2 |

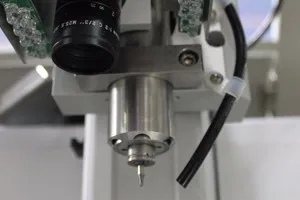

| Route Planning | Direct coordinate input or manual guiding with × 10 CCD camera |

| Safety Area Sensor | Standard |

| Bit Break Detection | Standard |

| Program Storage | HDD |

| Program Backup | USB |

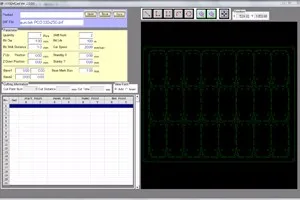

| Operating System | Windows 7 |

| Man-Machine Interface | Touchscreen Industrial Monitor + Keyboard + Mouse |

| Conveyor Adjustment | n/a |

| Conveyor load capacity | n/a |

| PCB Loading/Unloading | Manual |

| Power Supply | 3 Phase AC220V±5% 50 Hz/60Hz, 2.5 kw |

| Air | 0.5Mpa |

| Dimensions | (W)1347mm × (D)1039mm × (H)1403mm + 524mm signal tower |

| Weight | approx. 390 Kg |

| Base Height | 900mm |

| Vacuum Cleaner | YSF-V553 3HP 2.2 kw |

|

|

|

Routing Bit Sectioning

The

user may set a designated distance, and have the routing bit shift down

in order to make a new section of touting bit to cut boards for

multiplying the life of the routing bit.

|

2-Way Sliding Exchanger

This

work exchanger provides a simultaneously in-and out working space to

limit the idle time, which in turn reaches the utmost output value.

|

|

|

|

Multifunctional Automatic Tool/Blade Change System

When

the cutting blade reaches its limit, the system will replace with a new

blade and resume production automatically. It dramatically reduce

configuration time, maintenance related personnel cost.

|

Tool Break Detection & Bit Drop Detection Sensor During every routing task, this system will detect any variable change of bit, and notice the user with alarm system. Due to the reason that the condition of routing bit directly influences the cutting performance, we set up bit drop sensor to examine whether the bit is clipped properly and the using condition of bit. |

|

|

|

Safety Area Sensor

Aurotek

always pay our best attention to prevent any accident during operation

with immediate stop function and abide by CE standard. |

Off-Line Edited Program The users only need to upload AUTO CAD DXF to Off-Line Edited Program, use mouse to simply create cutting program. Then use USB storage device to save the edited program and upload to machine USB port. Simple and efficient. |

|

Linking Barcode Module & CIM / MES Function In response to Industry 4.0 era, the new complete data-integration function can be easily setup and collects massive real-time production information and uploads it to the central terminal server instantly. Furthermore, to accompany to the needs of various manufacturers, this function is designed based on open source code for faster user customization. The new complete data-integration function allows the system manager to effortlessly monitoring the complete production status through a centralized monitoring center, and make any production schedule adjustment accurately and efficiently. |

Email: caojun@hk-yush.com / evaliu@hk-yush.com