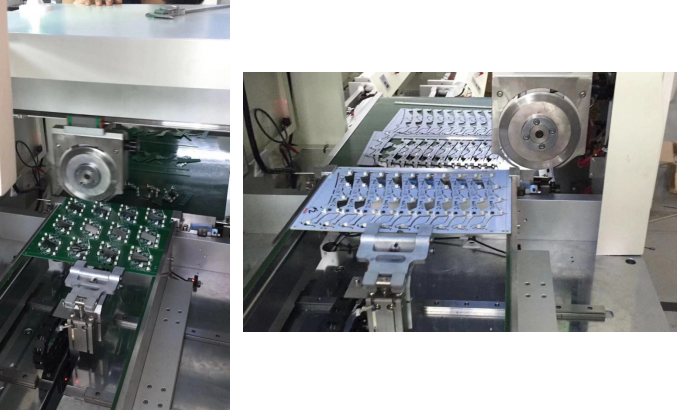

Main internal structure of the machine:

Features

1. PLC accurately controls the automation depaneling machine, and the machine can be connected to the pcb loader & unloader machine to realize unmanned operation and fully automated board separation.

2. Automatically feeding boards accurately, saving the trouble of manual v-cut socred, effectively improving the efficiency of the separate boards, and preventing the artificial waste plate from being caused by the slot.

3, The machine can save 100 sets of data, rapid replacement of PCB board, no need to re-write the parameters can be quickly changed board cutting, ordinary staff can quickly operate, a machine to achieve a variety of board type.

4. The stress of the knife-type pcb depaneling machine is relatively small, and it is suitable for PCB types. It is still the best choice for the circuit board with components on both sides, effectively avoiding problems such as dark-injury and cracking.

5.The machine can adjust the width of the feeder to adapt to a variety of specifications of the PCB board.

6. The machine with a conveyor belt, can transfer the divided PCB board to the production line.

7, high security, light curtain and guard knife double protection, ensure safe production.

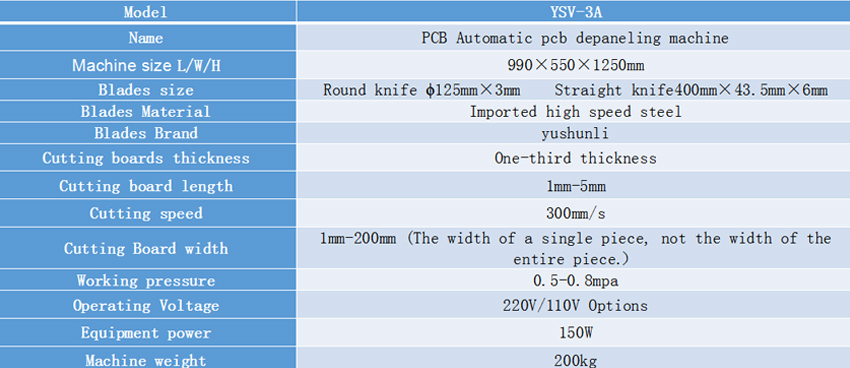

Technical Parameters:

Email: caojun@hk-yush.com / evaliu@hk-yush.com