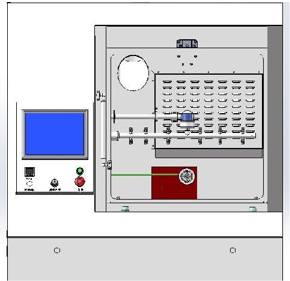

Device overview

1. For the surface cleaning of SMT PCB and PCBA boards in the electronics industry, the most advanced cleaning process in the industry is used to achieve 100% cleanliness and environmental protection.

2. The machine consists of cleaning system, rinsing system, fine rinsing, drying system and filtering system.

3. The equipment uses water-based liquid cleaning agent and DI water for rinsing, without any safety hazard, and no harm to personnel.

Cleaning objects:

PCBA Flux Cleaning Passive Components Flux Cleaning

Semicon Flux Cleaning

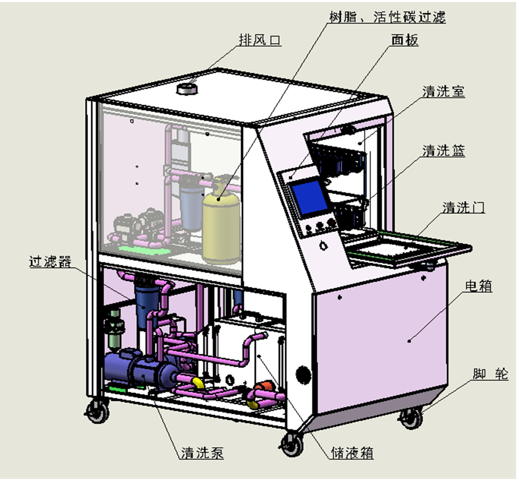

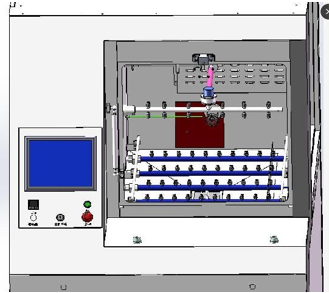

Main structural components:

The equipment is mainly composed of rack, spray cleaning system, spray rinsing system, fine rinsing system, cleaning basket moving mechanism, cleaning liquid tank, rinsing liquid tank, electric heating air system, water circulation system, spray room, hot air drying system, The electrical control box is composed.

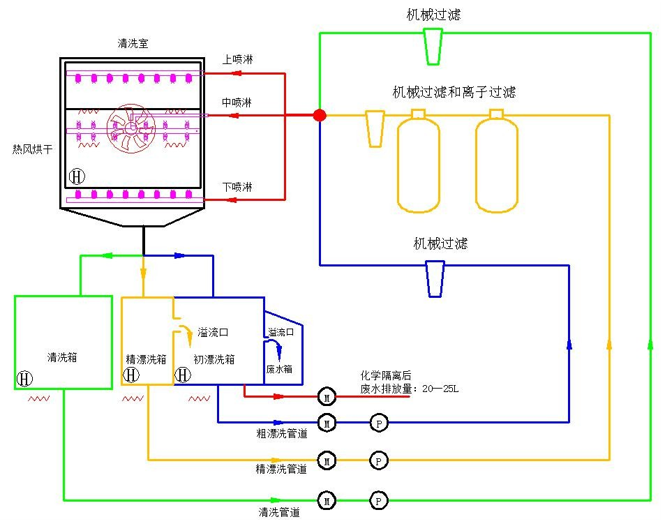

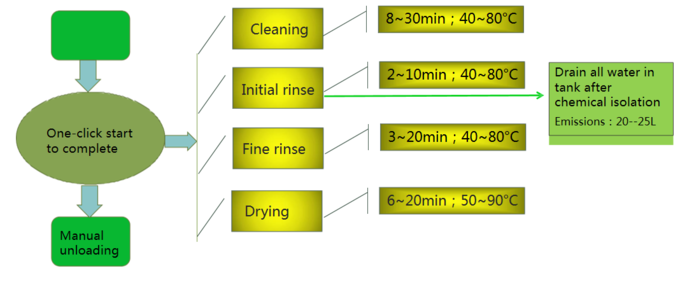

Working diagram:

a. The heating systems of the cleaning liquid tank, the fine rinsing liquid tank and the initial rinsing liquid tank are independently controlled.

b. Waste water is generated by overflow, which greatly saves water consumption.

Cleaning, fine rinsing, initial rinsing, equipped with independent pump, independent control, to eliminate the phenomenon of liquid channeling.

The chemical isolation ensures the cleanliness of the rinse water and improves the cleaning quality of the product.

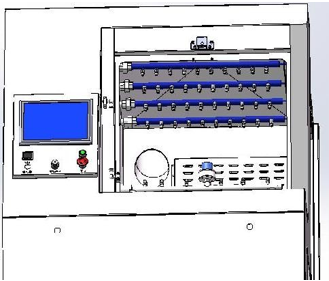

Introduction of Nozzle and Boom Structure

Adjustable nozzle pressure: 30~90PSI

Number of spray rods: 4 (fixed)

Schematic diagram of the upper spray boom Schematic diagram of the middle boom

1 in the middle (360°rotation) and 4 in the bottom (fixed); 9 in total

Number of nozzles: 98 refer to the diagram on the right

Advantages: to achieve all-round spray cleaning of PCBA without dead angle, which is superior to the traditional design of 360° rotating spray bars in the upper middle and lower parts.

Schematic diagram of the lower boom

Technical Specifications

Machine dimensions (mm):L1670*W1100*H1860

Voltage:Three-phase 380V (three-phase five-wire)

Total power:33KW

Rated current:50A

Gas source:0.4-0.6Mpa

Exhaust vent:Ø125

Cleaning tank volume:42L

Initial rinse tank volume:28L

Fine rinse tank volume:55L

Filter element:0.2μm

Basket size:500MM*550*100MM (upper and lower layers)

Cleaning time:8-10Min can be set

Cleaning method:Spray cleaning-spray initial rinsing-spray fine rinsing-wind drying

Operation control:PLC+touch screen (one key start)

Feature of product

1. A high-pressure spray system specially used for water-based cleaning solutions to clean PCB/PCBA and other processes.

2. Three-liquid tank, equipped with heating system, to meet the needs of cleaning, initial rinsing, fine rinsing and hot air drying.

3. Process flow: cleaning - chemical isolation - rinsing (open loop/closed loop) - drying.

4. Prepare advanced automatic touch screen operation software, save program files, use and simplify.

5. The system counting function can automatically accumulate the number of cleaning PCB boards and the number of circulating filtration times.

6. The liquid and pump pressure can be displayed through the panel pressure gauge, which can timely feedback the operation status of the equipment.

7. The cleaning pressure can be adjusted independently, with a visual window, and the pressure can be adjusted according to the cleaning requirements of the PCB board.

8. The conductivity monitors the rinsing solution to ensure cleanliness, and the conductivity can be set to meet the process requirements of different PCB boards.

9. The overall stainless steel body is sturdy and durable, resistant to acid, alkaline and other cleaning fluids.

10. The overflow method is adopted for rinsing, and the fine rinsing water overflows to the initial rinsing box, and there will be no repeated pollution.

11. High-pressure fan + hot air drying, the drying effect is faster and more thorough.

12. Lower operating cost, only 80-120ml of liquid is needed for each cleaning, and the residual liquid is directly recovered by the pipeline and pump after cleaning, which can reduce the consumption of liquid by 50%.

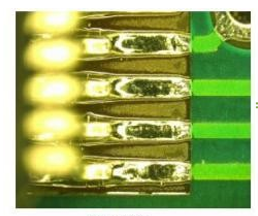

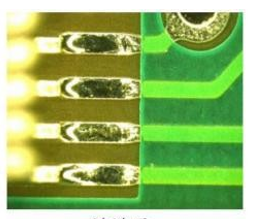

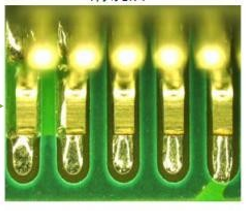

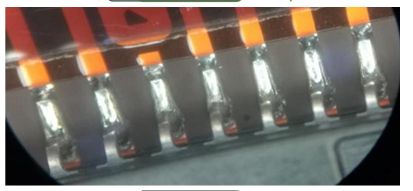

Comparison of cleaning examples

Before cleaning

After cleaning

Before cleaning

After cleaning

Email: caojun@hk-yush.com / evaliu@hk-yush.com