High Efficiency Environmentally friendly water-based online PCBA cleaning machine YSL-600-500

Feature

1. Fully automatic cleaning mode: The PCBA runs parallel on a mesh belt with a width of W600mm. Meanwhile, the heated cleaning solution is sprayed at high pressure and in equal directions through the spray arms.

The entire process of automatic cleaning, rinsing (opening the loop), and drying;

2. Full-process visualization: Tempered glass visualization window, making the cleaning process clear at a glance.

3. Scientific nozzle design (patent) : It adopts a gradually increasing distribution on both sides - thorough cleaning, and the spray arm and nozzle are detachable.

4. Adjustable pressure of the visual nozzle: It solves the problem of collision and splashing of small-sized workpieces under high-pressure spray conditions during cleaning.

5. The viewing window and the entrance are equipped with photoelectric protection to prevent the cleaning solution from splashing out, and the plate drop detection ensures its safety.

6. Comprehensive cleaning system: The standard dilution tank and spray rinse tank are both equipped with heating systems, which enhance the cleaning efficiency. Shorten the cleaning time and be compatible

Run water washing or chemical cleaning for SMT; Thoroughly and effectively clean the organic and inorganic contaminants such as rosin and solder paste remaining on the surface of THT's PCBA.

7. The built-in filtration system for cleaning and recovery has the function of compensating for the concentration of the cleaning solution. The solvent section is condensed and recovered for recycling, reducing the amount of solvent used.

8. Body material: The entire body is made of stainless steel, resistant to acidic, alkaline and other cleaning solutions.

9. Equip a UPS reserve power supply for protection. In case of a solid fault, it should have an emergency stop button and leakage protection function.

10. Lower operating costs: Lower equipment investment costs, localized services, teams, and abundant spare parts supply.

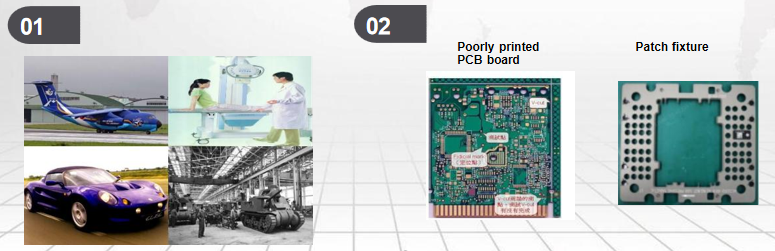

Aypplication field

The fully automatic water cleaning machine is an energy-saving, environmentally friendly, and batch cleaning integrated high-end comprehensive cleaning machine. It can fully automatically complete the functions of cleaning, rinsing (open loop/closed loop), and drying online.

1.It is mainly used for cleaning coated products and high-end precision products in military, aviation, aerospace electronics, medical, automotive new energy, automotive and other fields. It can effectively clean organic and inorganic contaminants such as rosin flux, water-soluble flux, no-cleaning

flux/solder paste remaining on the surface of SMT/THT PCBA after soldering

2. Cleaning of solder paste for poorly printed PCB boards, cleaning of solder paste for scrapers, etc.

Cleaning Value

Equipment Parametres

Content

Parameters

Size of the cleaning area

The total length of the three cleaning sections is 1140MM

Equipment appearance dimensions:

5000MM* 1960MM* 1840MM

Process flow:

Into the board section, water vapor separation, pre-cleaning - clean clean 1-2 - chemicals isolation - drainage chamber - rinse -- rinse -- rinse 1 2 - the final spray - wind cut 1 - the wind cut 2 - drying - the plate - drying 2 paragraphs

Capacity calculation

Mesh belt speed: Adjustable from 0.1 to 1.5 meters per minute. It is recommended to adjust the working speed to 0.4-0.5 meters per minute.

Reference: For 450mmX100mm plates, the plate placement spacing is 5mm, and the working speed is 0.5 meters per minute

Output: approximately 13 square meters per hour; Calculation method: Total width/Mesh belt speed

Example: 150*200mm plate, output per hour: approximately 450PCS/H. This output is for reference only and subject to actual conditions. Calculation method: total square meters/single square meters

Conveying surface height

950±50mm(adjust)

Entrance and exit direction:

Left in, right out (viewed from the front window of the unit)

Exhaust volume (air extraction volume) :

about36M³/Min ;Exhaust outlet diameter: 250mm, three at the front, middle and rear

Weight:

about1800KG

Power supply requirements

AC380/3P/50H;Total power: 102Kw/ 160A Rated operating power: 55Kw/85A

Email: caojun@hk-yush.com / evaliu@hk-yush.com